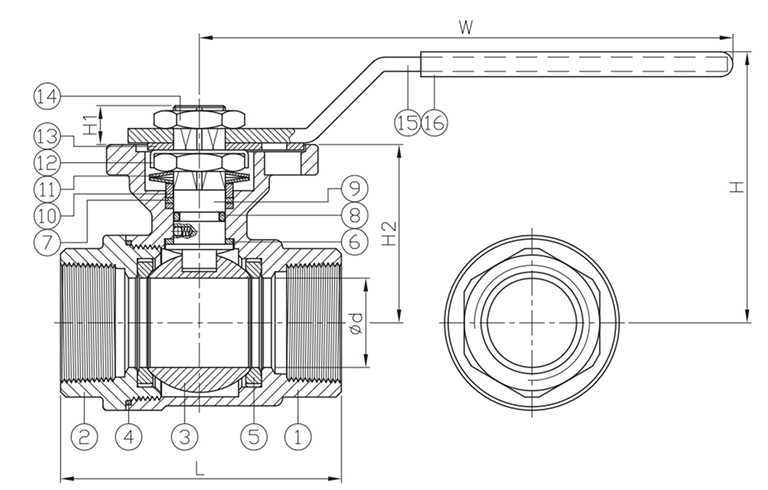

2006SD Series Ball Valve

1/2’’ - 3'' Sizes Available

(DN8~DN80)

The 2006SD Series Ball Valve from I-VAC is a high-performance, full-port valve designed for durability, reliability, and ease of automation. Built with precision investment casting and engineered for demanding applications, it offers excellent pressure and temperature ratings while ensuring safety with features like a blow-out proof stem, anti-static device, and locking mechanism. With universal ISO 5211 mounting capability and optional automation accessories, the 2006SD Series is a versatile solution for a wide range of industrial needs.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque in ipsum id orci porta dapibus. Vivamus magna justo, lacinia eget consectetur sed, convallis .

2-PC Threaded Ball Valve - Stainless Steel

PDF DOWNLOADS FOR: 2006D

Features :

- Investment Casting

- Full Port

- Available Sizes: 1/2″~3″ (DN8~DN80)

- Working Pressure: 1000 WOG (PN63)

- Working Temperature: -4°F~392°F (-20°C~200°C)

- Blow-Out Proof Stem: Standard

- Live-Loading Stem Design: Standard

- Anti-Static Device: Standard

- Locking Device: Standard

- Thread Type: ASME B1.20.1 (NPT) DIN2999 & BS21 ISO7/1 & EN10226

- End to End Length: Conforms to DIN 3202

- Fugitive Emission Approved: ISO 15848 Approval Optional

- Mounting Pad: ISO 5211 Direct Mounting Pad for Easy Automation

– Designed with universal mounting for use with ISO 5211 compliant valve automation equipment. - Automation Accessories: Optional

Available Automation Accessories

- Electric Actuators

- Pneumatic Actuators

- Limit Switches

- Mounting Kits

- Stem Extensions

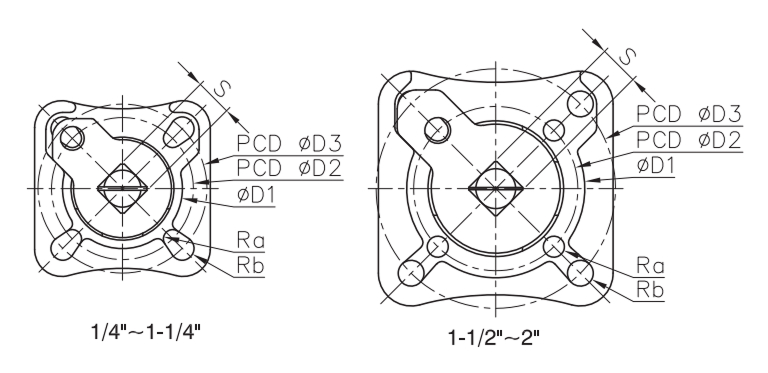

Dimension Charts

| NPS | d | L | H | H1 | H2 | W | S | D1 | D2 | D3 | Ra | Rb | ISO 5211 | Torque (in·lb) | Weight (lb) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 0.59 | 2.28 | 2.44 | 0.31 | 1.43 | 4.47 | 0.35 | 1.22 | 1.42 | 1.65 | 0.11 | 0.11 | F03/F04 | 48.7 | 0.8 |

| 3/4″ | 0.79 | 2.58 | 2.56 | 0.31 | 1.54 | 4.47 | 0.35 | 1.22 | 1.42 | 1.65 | 0.11 | 0.11 | F03/F04 | 66.4 | 1.0 |

| 1″ | 0.98 | 3.10 | 2.90 | 0.46 | 1.92 | 5.51 | 0.43 | 1.40 | 1.65 | 1.97 | 0.11 | 0.11 | F04/F05 | 97.4 | 1.8 |

| 1-1/4″ | 1.26 | 3.54 | 3.21 | 0.45 | 2.13 | 5.51 | 0.43 | 1.40 | 1.65 | 1.97 | 0.11 | 0.11 | F04/F05 | 132.8 | 2.7 |

| 1-1/2″ | 1.50 | 4.13 | 4.06 | 0.44 | 2.59 | 6.77 | 0.55 | 2.20 | 1.97 | 2.76 | 0.14 | 0.18 | F05/F07 | 177 | 4.4 |

| 2″ | 1.97 | 4.88 | 4.39 | 0.41 | 2.97 | 6.77 | 0.55 | 2.20 | 1.97 | 2.76 | 0.14 | 0.18 | F05/F07 | 354 | 6.4 |

| 2.5″ | 2.48 | 5.76 | 5.55 | 0.67 | 3.6 | 12.8 | 0.67 | 2.99 | 2.76 | 4.02 | 0.18 | 0.22 | F05/F07 | 531 | 13.2 |

| 3″ | 2.99 | 6.44 | 6.91 | 0.65 | 3.97 | 12.8 | 0.67 | 2.99 | 2.76 | 4.02 | 0.18 | 0.22 | F05/F07 | 752.3 | 15.9 |

unit: in

| DN | d | L | H | H1 | H2 | W | S | D1 | D2 | D3 | Ra | Rb | ISO 5211 | Torque (N·m) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 11.6 | 58 | 62 | 8 | 36.4 | 113.5 | 9 | 31 | 36 | 42 | 2.75 | 2.75 | F03/F04 | 5.5 | 0.4 |

| 10 | 12.7 | 58 | 62 | 8 | 36.4 | 113.5 | 9 | 31 | 36 | 42 | 2.75 | 2.75 | F03/F04 | 5.5 | 0.4 |

| 15 | 15 | 58 | 62 | 8 | 36.4 | 113.5 | 9 | 31 | 36 | 42 | 2.75 | 2.75 | F03/F04 | 5.5 | 0.4 |

| 20 | 20 | 65.6 | 65 | 8 | 39.2 | 113.5 | 9 | 31 | 36 | 42 | 2.75 | 2.75 | F03/F04 | 7.5 | 0.5 |

| 25 | 25 | 78.7 | 76 | 11.8 | 48.7 | 140 | 11 | 35.5 | 42 | 50 | 2.75 | 3.5 | F04/F05 | 11 | 0.8 |

| 32 | 32 | 90 | 81.5 | 11.5 | 54.2 | 140 | 11 | 35.5 | 42 | 50 | 2.75 | 3.5 | F04/F05 | 15 | 1.2 |

| 40 | 38 | 105 | 103 | 11.3 | 65.7 | 172 | 14 | 56 | 50 | 70 | 3.5 | 4.5 | F05/F07 | 20 | 2 |

| 50 | 50 | 124 | 111.5 | 10.4 | 75.5 | 172 | 14 | 56 | 50 | 70 | 3.5 | 4.5 | F05/F07 | 40 | 2.9 |

| 65 | 63 | 146.2 | 141 | 17 | 91.5 | 325 | 17 | 76 | 70 | 102 | 4.5 | 5.5 | F05/F07 | 60 | 6 |

| 80 | 76 | 163.7 | 150 | 16.5 | 100.75 | 325 | 17 | 76 | 70 | 102 | 4.5 | 5.5 | F05/F07 | 85 | 7.2 |

unit: mm